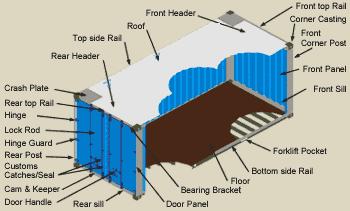

Most shipping containers will have maneuverable cargo doors split down the middle to form two separate steel doors. Component #4) Cargo Doors, Headers, and Sills Cross members create extra space between the ground and the flooring to stop moisture from actually affecting the floor of the shipping container proper. These cross members can lift the greater shipping container structure off the ground, which is also why many shipping container structures don’t need foundations. Component #3) Beams/Joists/Cross MembersĬross members, which may also be called beams and joists, support shipping container floors by “crossing” from side to side. These corner castings and posts are designed to be strong enough to be rigged to cranes, even if they have a full shipment of goods inside. Component #2) Corner Castings and PostsĬorner castings are reinforced shipping container corners that often have openings for twist locks. Some aftermarket vents can also be durable plastic. Vents can be made with the same type of Corten steel as the containers or from other metals.

Most shipping containers feature vents which allow air flow in and out of the container and help with temperature regulation and moisture control. Since shipping containers need to be made to specific standards that ensure container longevity as well as user and product safety, most of them have the same number and types of components. Recommended Reading: Buyer’s Guide To Shipping Containers Let’s break down the key shipping container materials and terminology you need to know if you are purchasing, building, or modifying a shipping container for your own purposes.

But beyond these slight differences, steel shipping containers are largely manufactured with the same materials and components as one another. Shipping containers come in two major sizes – 20’ and 40’ – and a wide variety of colors.

0 kommentar(er)

0 kommentar(er)